Applicable instructions for FRP storage tank products

Technical characteristics

(1) On-site vertical winding technology, customers can effectively supervise and effectively control product quality.

(2) The head pieces are made in a professional FRP factory and spliced on site.

(4) For high-end customers, select metal mold mirror lining technology to ensure that the shape of the cylinder is accurate and the lining is smooth.

(5) The unidirectional cloth is added when the cylinder is wound, which can effectively enhance the axial strength.

(6) The cylinder body and the tank bottom adopt plug-in connection or butt connection. Customers can choose by themselves.

Features

(1) Use computer to control equipment operation.

(2) Using high-power variable-frequency speed-regulating motor as strong power, the total drive of the equipment reaches 50 tons, which is currently the largest vertical winding machine in China.

(3) The three-dimensional steel structure mold is used to fully ensure the overall structural strength of the mold and the accurate geometric shape/size. The maximum winding diameter can reach 25 meters.

(4) Use a large flow resin spray gun to ensure the quality of the inner lining.

(5) It can wind up to 60 non-alkali glass fiber winding yarns at the same time, the yarn width can reach 120mm, and the winding speed is fast.

(6) The advanced dipping tank can ensure the speed of resin infiltration and effectively ensure the strength of the cylinder.

(7) It has the highest winding trolley in the country at present, with a lifting range of 0-10 meters, which can be wound with a 10-meter cylinder at one time, without joints inside and outside.

(8) The power/control part of the equipment adopts Siemens components, which has good reliability.

(9) All equipment components can be transported to the construction site on a 10-ton lengthened truck.

Process flow

The process flow diagram is as follows:

Description:

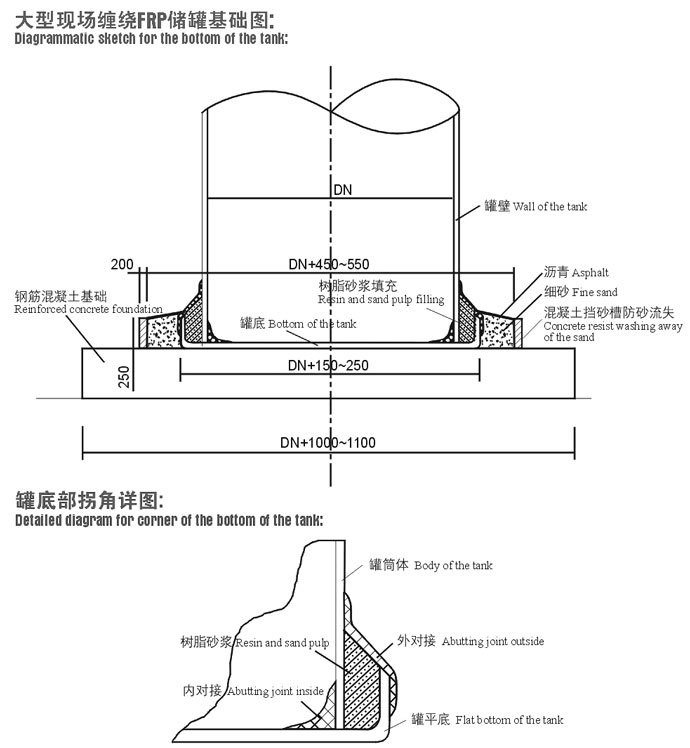

1. The surface of the foundation must be very smooth, with unevenness less than or equal to 3mm/m.

2. The bottom of the storage tank is directly pasted on the basis of the storage tank.

3. After the storage tank is in place and the pipe is installed, the sand retaining groove is made.

| Parameter table of on-site vertical winding large glass fiber reinforced plastic storage tank | |||||||||||

| size (mm) | volume(m3) | highness(mm) | size (mm) | volume(m3) | highness(mm) | size (mm) | volume(m3) | highness(mm) | size (mm) | volume(m3) | highness(mm) |

| 4000 | 75 | 5970 | 7500 | 400 | 9050 | 9500 | 500 | 7050 | 12000 | 500 | 4420 |

| 100 | 7960 | 450 | 10190 | 550 | 7760 | 550 | 4860 | ||||

| 125 | 9950 | 500 | 11320 | 600 | 8460 | 600 | 5310 | ||||

| 4500 | 75 | 4720 | 8000 | 150 | 2980 | 650 | 9170 | 650 | 5750 | ||

| 100 | 6290 | 200 | 3980 | 700 | 9880 | 700 | 6190 | ||||

| 125 | 7860 | 250 | 4970 | 750 | 10580 | 750 | 6630 | ||||

| 150 | 9430 | 300 | 5970 | 800 | 11290 | 800 | 7070 | ||||

| 5000 | 100 | 5090 | 350 | 6960 | 10000 | 300 | 3820 | 850 | 7520 | ||

| 125 | 6370 | 400 | 7960 | 350 | 4460 | 900 | 7960 | ||||

| 150 | 7640 | 450 | 8950 | 400 | 5090 | 950 | 8400 | ||||

| 200 | 10190 | 500 | 9950 | 450 | 5730 | 1000 | 8840 | ||||

| 5500 | 100 | 4210 | 550 | 10940 | 500 | 6370 | 1100 | 9730 | |||

| 125 | 5260 | 600 | 11940 | 550 | 7000 | 1200 | 10610 | ||||

| 150 | 6310 | 8500 | 200 | 3520 | 600 | 7640 | 1300 | 11490 | |||

| 200 | 8420 | 250 | 4410 | 650 | 8280 | 13000 | 300 | 2260 | |||

| 250 | 10520 | 300 | 5290 | 700 | 8910 | 400 | 3010 | ||||

| 6000 | 125 | 4420 | 350 | 6170 | 750 | 9550 | 500 | 3770 | |||

| 150 | 5310 | 400 | 7050 | 800 | 10190 | 600 | 4520 | ||||

| 200 | 7070 | 450 | 7930 | 850 | 10820 | 700 | 5270 | ||||

| 250 | 8840 | 500 | 8810 | 900 | 11460 | 800 | 6030 | ||||

| 300 | 10610 | 550 | 9690 | 11000 | 300 | 3160 | 900 | 6780 | |||

| 6500 | 125 | 3770 | 600 | 10570 | 350 | 3680 | 1000 | 7530 | |||

| 150 | 4520 | 650 | 11450 | 400 | 4210 | 1100 | 8290 | ||||

| 200 | 6030 | 9000 | 200 | 3140 | 450 | 4740 | 1200 | 9040 | |||

| 250 | 7530 | 250 | 3930 | 500 | 5260 | 1300 | 9790 | ||||

| 300 | 9040 | 300 | 4720 | 550 | 5790 | 1400 | 10550 | ||||

| 350 | 10550 | 350 | 5500 | 600 | 6310 | 1500 | 11300 | ||||

| 7000 | 125 | 3250 | 400 | 6290 | 650 | 6840 | 14000 | 300 | 1950 | ||

| 150 | 3900 | 450 | 7070 | 700 | 7310 | 400 | 2600 | ||||

| 200 | 5200 | 500 | 7860 | 750 | 7890 | 500 | 3250 | ||||

| 250 | 6500 | 550 | 8650 | 800 | 8420 | 600 | 3900 | ||||

| 300 | 7800 | 600 | 9430 | 850 | 8940 | 700 | 4550 | ||||

| 350 | 9090 | 650 | 10220 | 900 | 9470 | 800 | 5200 | ||||

| 400 | 10390 | 700 | 11000 | 950 | 10000 | 900 | 5850 | ||||

| 7500 | 125 | 2830 | 750 | 11790 | 1000 | 10520 | 1000 | 6500 | |||

| 150 | 3400 | 9500 | 250 | 3530 | 1100 | 11570 | 1100 | 7150 | |||

| 200 | 4530 | 300 | 4230 | 12000 | 300 | 2650 | 1200 | 7800 | |||

| 250 | 5660 | 350 | 4940 | 350 | 3090 | 1300 | 8440 | ||||

| 300 | 6790 | 400 | 5640 | 400 | 3540 | 1400 | 9090 | ||||

| 350 | 7920 | 450 | 6350 | 450 | 3980 | 1500 | 9740 | ||||

| Parameter table of field winding large storage tank | |||||||||||

| size (mm) | volume(m3) | highness(mm) | size (mm) | volume (m3) | highness(mm) | size (mm) | volume(m3) | highness(mm) | size (mm) | volume(m3) | highness(mm) |

| 14000 | 1600 | 10390 | 17000 | 900 | 3970 | 19000 | 2000 | 7050 | 23000 | 1100 | 2650 |

| 1700 | 11040 | 1000 | 4410 | 20000 | 800 | 2550 | 1200 | 2890 | |||

| 1800 | 11690 | 1100 | 4850 | 900 | 2860 | 1300 | 3130 | ||||

| 15000 | 400 | 2260 | 1200 | 5290 | 1000 | 3180 | 1400 | 3370 | |||

| 500 | 2830 | 1300 | 5730 | 1100 | 3500 | 1500 | 3610 | ||||

| 600 | 3400 | 1400 | 6170 | 1200 | 3820 | 1600 | 3850 | ||||

| 700 | 3960 | 1500 | 6610 | 1300 | 4140 | 1700 | 4090 | ||||

| 800 | 4530 | 1600 | 7050 | 1400 | 4460 | 1800 | 4330 | ||||

| 900 | 5090 | 1700 | 7490 | 1500 | 4770 | 1900 | 4570 | ||||

| 1000 | 5660 | 1800 | 7930 | 1600 | 5090 | 2000 | 4810 | ||||

| 1100 | 6220 | 1900 | 8370 | 1700 | 5410 | 24000 | 1100 | 2430 | |||

| 1200 | 6790 | 2000 | 8810 | 1800 | 5730 | 1200 | 2650 | ||||

| 1300 | 7360 | 18000 | 600 | 2360 | 1900 | 6050 | 1300 | 2870 | |||

| 1400 | 7920 | 700 | 2750 | 2000 | 6370 | 1400 | 3090 | ||||

| 1500 | 8490 | 800 | 3140 | 21000 | 800 | 2310 | 1500 | 3320 | |||

| 1600 | 9050 | 900 | 3540 | 900 | 2600 | 1600 | 3540 | ||||

| 1700 | 9620 | 1000 | 3930 | 1000 | 2890 | 1700 | 3760 | ||||

| 1800 | 10190 | 1100 | 4320 | 1100 | 3180 | 1800 | 3980 | ||||

| 1900 | 10750 | 1200 | 4720 | 1200 | 3460 | 1900 | 4200 | ||||

| 2000 | 11320 | 1300 | 5110 | 1300 | 3750 | 2000 | 4420 | ||||

| 16000 | 500 | 2490 | 1400 | 5500 | 1400 | 4040 | 25000 | 1200 | 2440 | ||

| 600 | 2980 | 1500 | 5890 | 1500 | 4330 | 1300 | 2650 | ||||

| 700 | 3480 | 1600 | 6290 | 1600 | 4620 | 1400 | 2850 | ||||

| 800 | 3980 | 1700 | 6680 | 1700 | 4910 | 1500 | 3060 | ||||

| 900 | 4480 | 1800 | 7070 | 1800 | 5200 | 1600 | 3260 | ||||

| 1000 | 4970 | 1900 | 7470 | 1900 | 5490 | 1700 | 3460 | ||||

| 1100 | 5470 | 2000 | 7860 | 2000 | 5770 | 1800 | 3670 | ||||

| 1200 | 5970 | 19000 | 700 | 2470 | 22000 | 900 | 2370 | 1900 | 3870 | ||

| 1300 | 6470 | 800 | 2820 | 1000 | 2630 | 2000 | 4070 | ||||

| 1400 | 6960 | 900 | 3170 | 1100 | 2890 | ||||||

| 1500 | 7460 | 1000 | 3530 | 1200 | 3160 | ||||||

| 1600 | 7960 | 1100 | 3880 | 1300 | 3420 | ||||||

| 1700 | 8460 | 1200 | 4230 | 1400 | 3680 | ||||||

| 1800 | 8950 | 1300 | 4590 | 1500 | 3950 | ||||||

| 1900 | 9450 | 1400 | 4940 | 1600 | 4210 | ||||||

| 2000 | 9950 | 1500 | 5290 | 1700 | 4470 | ||||||

| 17000 | 500 | 2200 | 1600 | 5640 | 1800 | 4740 | |||||

| 600 | 2640 | 1700 | 6000 | 1900 | 5000 | ||||||

| 700 | 3080 | 1800 | 6350 | 2000 | 5260 | ||||||

| 800 | 3520 | 1900 | 6700 | 23000 | 1000 | 2410 | |||||